I don’t normally do guitar repairs, preferring to build my own instruments. This is not a statement that I think building is more difficult or challenging, quite the contrary. I merely feel it fits my temperament better. However when The Fret House in Covina was in between repairmen, I told Tom Seymour, its owner, I would help out until he found someone permanent. He’s owned the store for over thirty years and still has the same passion for the instrument as he did when he opened the store. Tom is a great guy and his store was the first to carry my guitars.

One of the instruments the previous repairman had left was a Gibson Style O Artist. It was literally a basket case and nothing more than pieces. Half a fretboard, part of the back missing and a top that had been thinned with new braces put in. I thought wow, that’s interesting, but what a job that’s going to be.

One of the repairs I had done was a Gibson HG, circa mid thirties. It had a shattered top and numerous other problems. Its owner, Jim Richardson, also owned the Style O which, as I was to find out, had been there for four and a half years. When I took on the HG, we kind of used that as a trial run for both of us on the possibility that I would resurrect the Style O. The HG went well and I found Jim to be reasonable about what could be accomplished and open to my suggestions of what should be done along the way.

Over lunch we talked about his acquisition and I asked him to contribute on how he came by the guitar.

“It was late Spring of 1976 when I first saw a Gibson Style O Artist. As a student at the University of California, Santa Barbara, the only entertainment I could afford involved visiting music stores and playing their vintage guitars. Dropping into a tiny music store on the outskirts of Santa Barbara, all thoughts of Firebirds and Jaguars were driven from my mind when I was confronted by the largest and strangest acoustic guitar I had ever seen. Eighteen inches across and topped by a curlicue, the guitar stunned me with its outlandish appearance.

Playing the O Artist was a revelation. Although I had to wrestle a neck that more than filled my hand, the thick, woody tone matched every ragtime lick I threw at it. As much as I loved my D-18 (purchased on a rent-to-own program), I could see that its sound was too modern for the music I wanted to play.

Although I considered the $750 price tag fair, it was far beyond my means. Barely able to make rent each month, the most I could do was visit the guitar every weekend until the day came when it was purchased and left my life forever.

Twenty-five years later my circumstances had improved and I was married to a woman sympathetic to my need to purchase derelict stringed instruments and have them repaired to playing condition. Our collection was small, but meaningful. The highlights have included: a 1948 Martin 0-18 found in Guatemala during our honeymoon (formerly owned by the leader of a Mayan marimba band), headstock chiseled to accommodate classical tuners; a 1930s-era Gibson HG-0 with a shattered top and a spray-painted finish; a 1936 Gibson L-10 archtop with a sunken top possibly caused by spending almost 70 years in a modified banjo tuning; a 1952 Kay K-161 (Jimmy Reed model) dropped during a gig; a 1923 Gibson H-1 mandola missing the headstock.

A number of these “treasures” had been found on eBay, so that’s where I turned after the cover of a Big Bill Broonzy CD reminded me of the lost Style O Artist. My search was immediately fruitful. A 1920 O Artist had fallen victim to an amateur luthier: Almost all the finish had been removed, most of the binding had been replaced with vinyl weather stripping and the top had been routed to accommodate the extra width of the new “binding.” Missing were one set of tuners and the pickguard. The original tailpiece was present, but broken. The top was cracked, a piece of the back had been replaced with plywood and a section of the side was severely cracked. It was the perfect guitar for our collection.

Soon after the guitar arrived my wife and I took it the Fret House in Covina, California, for repair and restoration. Our Martin O-18 had been repaired there and we loved the shop for its atmosphere, fine guitars and the expert advice available from the staff”.

Okay, after hearing that I was hooked. In addition to the fact I liked the guy and felt sorry for him because this thing had been in pieces for over four years, I agreed to take it on because of the challenge it presented. I might never get a chance to work on such an instrument again. I agreed to honor the price the previous repairman had worked up, $1,100.00. I thought it was a low but it was still a substantial amount of money.

My first step was to research the instrument to try and find out as much as I could. Jim had talked to George Gruhn of Gruhn Guitars in Nashville who had once owned a Style O as a personal instrument He would use the information in an attempt to push the old repairman in the right direction when he hit roadblocks. As such, he knew quite a bit about the guitar. The label was gone but the serial number was written in blue ink or pencil where it had been. 66950 could clearly be seen and from a web search of www.guitarhq.com it was determined that the guitar was made in the middle of 1921. The order number on the inside of the head block was illegible. I also got some valuable pictures from Frank Ford’s www.frets.com and from the web site run by the National Music Museum located on the campus of The University of South Dakota, Included in this site were some great pictures of an O Artist from 1915, one of which was a close up of the label from that period. It was decided that I would make a reproduction of the label and document the fact in a smaller label underneath the soundboard, along with my name.

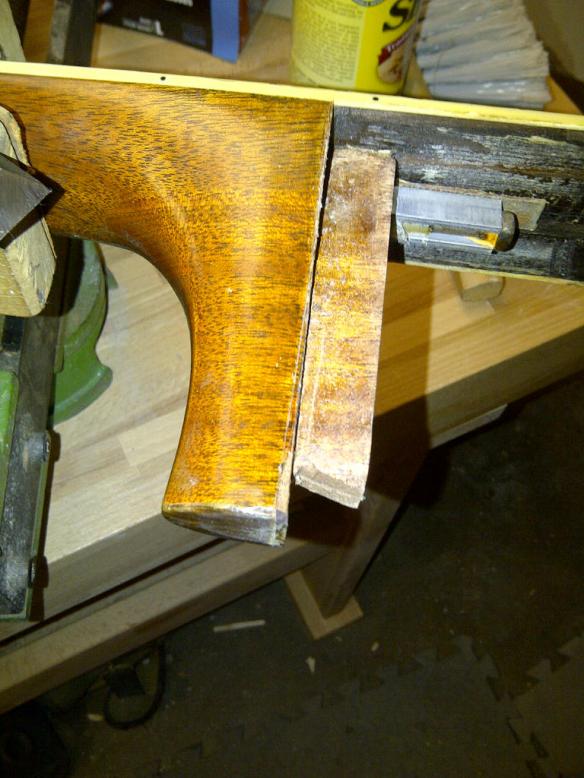

Jim wanted an instrument he could play and not just hang on the wall. At his request the top had been thinned with new braces so even if I had wanted to return the guitar to original 1921 specs it would have been impossible. It was more what could be described as a resurrection not a restoration. Jim said he “wanted to be the coolest guy in the nursing home”, and that sounded like the right attitude to me. I would not be using hide glue or varnish for a finish. The neck was over an inch and seven eighths wide and seven eighths thick with out the fretboard. It was to be taken down so it could be playable, so we used the measurements from a guitar in his possession. He also wanted a truss rod installed and modern Waverlys, instead of the three in-line tuners that came on the guitar. I had no problems with this because the guitar was in such bad shape, and it was to be a player.

The previous repairman had done a good job of splicing the side that was too damaged to repair. Unfortunately he didn’t leave enough to use the pieces of the original wedge. He had taken the guitar completely apart to affect the repair, but curiously he had re-glued the head block to the top and started to re-bind the body before the body was put together. My guess is that he did this to try and compensate for the wide binding channel created by the vinyl “binding”. I thought that this was a mistake and my first step would be to take the new ivoroid binding off and take the top back off what was left of the sides. This was done using a silicone heating blanket to liberate the sides and acetone to remove the binding.

When this was done I created a mold of the guitar of the top using two thickness’ of particle board to rebuild the sides.

I decided to make a new larger wedge so that I would not have to re-do his side graft. I thought I would have enough to do as it was. One of the sides was badly crinkled at the waist. So my first step would be to put the side back into shape with a bending iron. Once that was done I cleaned up the end block and glued it to the grafted side. There was only a small 14”section of the kerfing left and it appeared to be spruce. I couldn’t find a supplier for it so I decided to make it myself. I used my fret slotting jig to create the kerfing by putting a small piece of X-acto knife blade on the fence to use it as an indexer. After the first slot is cut I move the freshly cut slot to the pin to cut the next slot. This is repeated until I have enough to get the job done. After installing the kerfing, I leveled the sides with a chisel and sanding block so that I would have a fresh surface to glue the top and back.

There were ghost images about 5/8” wide of what were side reinforcements. Having not seen another Gibson from that period, I’m not positive but I assume they were hide glue soaked linen. I thought because of the damage to the sides it needed something more, so I used 1/8” quartered spruce of the same footprint to bind them together.

Making a mahogany plug, I filled the end pin hole so that if there was any misalignment it wouldn’t be a problem. The last thing was to make the wedge. As I said the sides were a little short so I matched the color of the original wood used and made it a little bigger.

Now on to the top… It was in as bad shape as the sides. All the pieces were there, but there were several cracks and fissures. They had already been glued together, but somewhat sloppily. I did the best I could to clean them up, putting cleats on the inside to shore them up. I cleaned the edges where the kerfing was and put on a label stating that I had restored the guitar, the date and that the manufacturer’s label was a reproduction.

Part 2 next week…

The first thing I do is to square it off with a plane, then cut the truss rod channel and the two channels for the graphite reinforcement. Once this is done I cut the profile for the neck and glue on the peghead overlay, in this case, book matched camatillo. My client wanted a slotted peghead so I used a jig I made to cut the appropriate slots.

The first thing I do is to square it off with a plane, then cut the truss rod channel and the two channels for the graphite reinforcement. Once this is done I cut the profile for the neck and glue on the peghead overlay, in this case, book matched camatillo. My client wanted a slotted peghead so I used a jig I made to cut the appropriate slots.  After the truss rod and the graphite bars are installed the head stock is inlayed with my logo and the fingerboard prepped.

After the truss rod and the graphite bars are installed the head stock is inlayed with my logo and the fingerboard prepped.  In this case the fretboard is bound in rosewood to match the binding on the body.

In this case the fretboard is bound in rosewood to match the binding on the body.